Computation of the ship hull flow with the help of complexes of hydrodynamical analysis now gets the increasing practical value in the domestic and foreign design organizations.

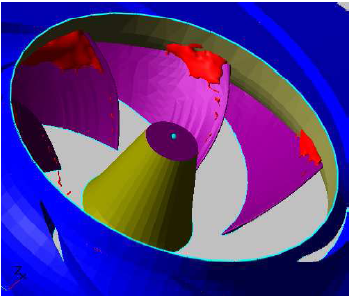

CFD analysis of two first - stage centrifugal impellers is undertaken with the main goal to obtain additional evaluation data regarding flow characteristics of the old first stage impeller design and in the proposed new cantilever impeller design.

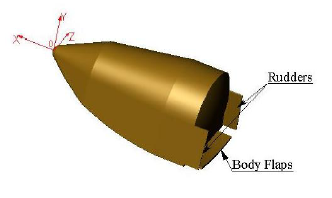

At present time RSC Energia is carrying out research work on designing the reentry manned spacecraft of new generation to crew deliver, in-flight support and return. The spacecraft ought to take the place of Soyuz. Manned spacecraft Clipper having the reentry vehicle (RV) of lifting body type is a possible alternate solution (Fig. 1). In comparison with Soyuz suggested RV provides higher maneuverability and less overloading during descent phase.

An advanced finite-volume method (method of modified finite volumes) for numerical simulation of flows in industrial applications and its implementation in code FlowVision is proposed. The method is based on non-staggered Cartesian grid with adaptive local refinement and a subgrid geometry resolution method for description of curvilinear complex boundaries. Semi-Lagrange approach for solution of convective transport equation and splitting algorithm for

solution of Navier-Stokes equations are presented.

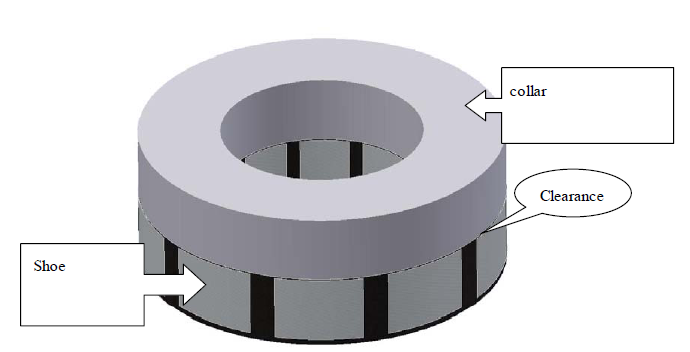

Lift force formation in a thrust bearing of 800-tons rotor of electric power station is discussed in the given paper. The problem is solved numerically. Direct coupling between finite-element system Abaqus calculating stress and strain state of an bearing parts and finite-volume system FlowVision-HPC calculating oil flow in gap between a collar and a shoe of bearing is used. The shape of the gap between the shoe and the collar, the clearance value, the moment of the friction force, and the temperature distribution of oil over the clearance are determined.

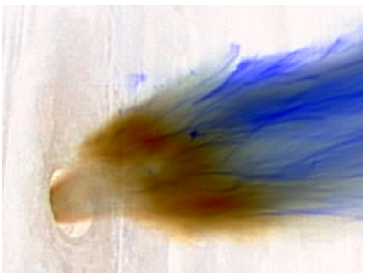

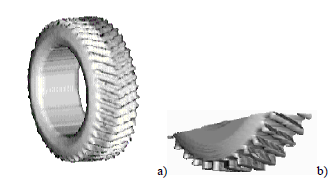

Approach to numerical simulation of water and air flow around aquaplaning car tire is described. The approach for governing equations solving is based on a finite-volume method and non-staggered Cartesian adaptive locally refined grid. A method of subgrid geometry resolution is proposed for accurate

description of curvilinear complex boundaries. This method uses a presentation of boundaries as a set of plane facets and makes CFD code compatible with CAD systems. The described technology is implemented in FlowVision code. Some results of simulation of car tire aquaplaning performed by FlowVision are presented The tire lift dependence on a tread picture is calculated.

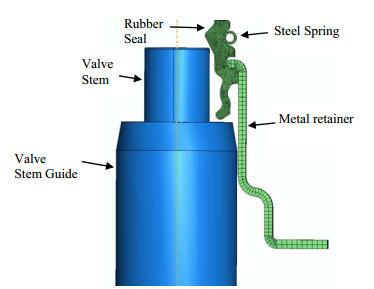

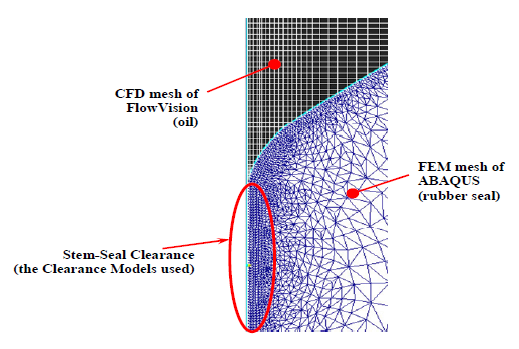

The valve stem seal is an important part of any internal combustion engine. The seal supplies a lubrication of valve stem and limits emission of oil. To design reliable and long-life stem seals a numerical simulation of the seal work is used. Numerical simulation helps to understand the main features of the stem seal working cycle and estimate the changing seal characteristics because of seal aging processes. The problem of oil flow via stem seal involves fluid-structure interaction between an oil flow induced by oscillating stem and deformable seal made from rubber. The Fluid-Structure Interaction Problem is solved numerically by using two codes: Abaqus/Explicit to get deformation of rubber seal and CFD code FlowVision to simulate oil flow.

The first valve stem seal was invented in 1958. It was made up of Buna-N (NBR) Elastomer Body, Ring retainer, Teflon insert working in a 400°F temperature environment. In the early days before the invention of valve stem seals, there was higher oil consumption, excess blow by through the valves and high wear of the valves.